Mastering Radiation in Scrap Yards: Your Ultimate Guide to Detection & Safety

Uncover the risks of radioactive scrap & learn how radiation detection protects your scrap yard. Essential guide to safety, compliance & preventing costly incidents.

The scrap metal industry is vital, but an invisible threat lurks: radiation in scrap yards. Undetected radioactive materials can lead to catastrophic financial losses, severe health risks, and irreparable reputational damage. This comprehensive guide will walk you through understanding this unseen danger, the devastating costs of contamination, essential scrap metal radiation detection technologies, crucial response protocols, and how to build a robust radiation safety culture. Protecting your business, employees, and community starts here.

The Silent Saboteur: Understanding Radioactive Scrap Metal Threats

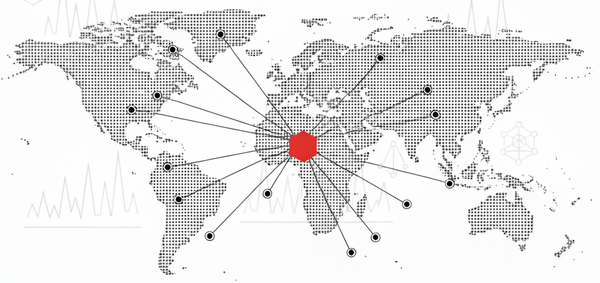

Radioactive materials are increasingly, and often inadvertently, entering the global scrap metal stream. This isn't just a rare occurrence; it's a growing concern for every scrap yard. The danger comes in two main forms:

"Orphan Sources": Lost, Stolen, and Deadly Dangers in Scrap

"Orphan sources" are radioactive materials, often sealed in protective metal casings, that have fallen out of regulatory control.

- Origins: Commonly found in improperly disposed of industrial gauges (measuring density, level, thickness), medical equipment (like old radiotherapy units containing Cobalt-60 or Cesium-137), well-logging tools, or even stolen devices.

- Risk: Though often small, they can be highly radioactive. If breached during scrap processing (shearing, shredding) or melted, they can release hazardous radiation, posing acute health risks and causing widespread contamination. [Internal Link Idea: Link to a more detailed article on "Common Types of Orphan Sources Found in Scrap Metal"]

- The Complacency Trap: While individual encounters seem unlikely to workers, industry data shows a different story. The US experiences roughly one lost or stolen source per day, and UK shredders find multiple sources annually.

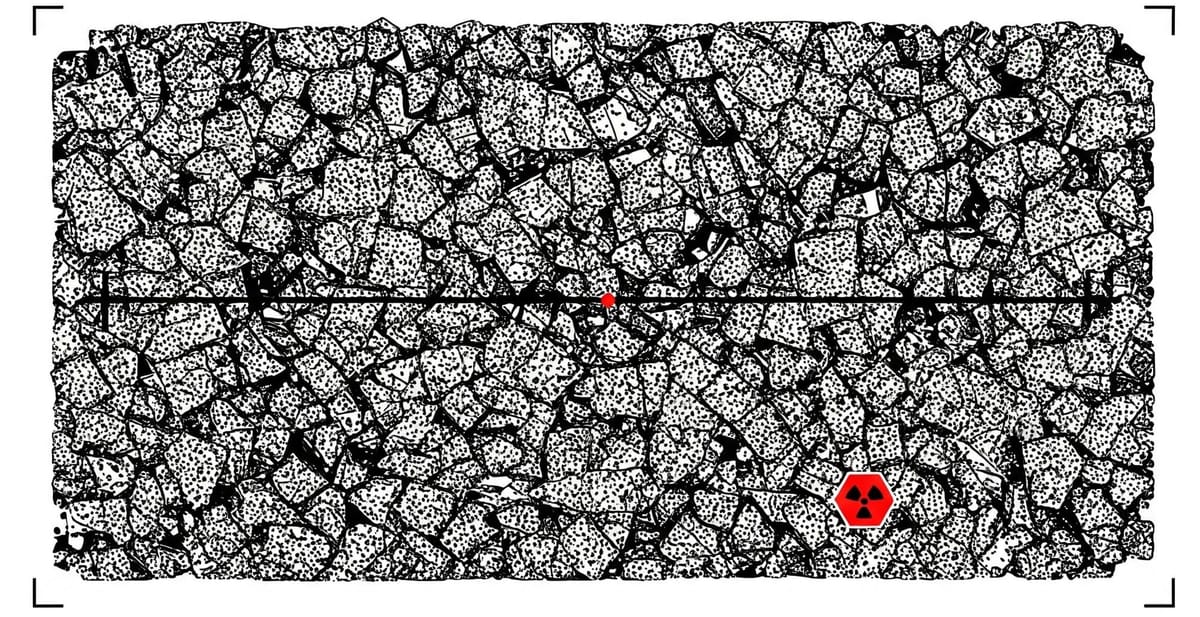

NORM & TENORM: The Pervasive Background Radiation Challenge

Distinct from discrete orphan sources is Naturally Occurring Radioactive Material (NORM) and its technologically enhanced counterpart (TENORM).

- Definition: NORM includes elements like Uranium, Thorium, and Radium found naturally in the earth. TENORM is NORM concentrated by industrial processes.

- Sources in Scrap: Found in oil and gas production wastes (pipe scale), mining residues, water treatment filters, refractory bricks, and some metal alloys.

- Challenge: While typically lower in activity per unit than orphan sources, NORM/TENORM can be present in large volumes. It can trigger sensitive radiation monitors for scrap, requiring methods to differentiate it from more dangerous artificial isotopes. The primary health concern is often internal exposure from inhaling contaminated dust.

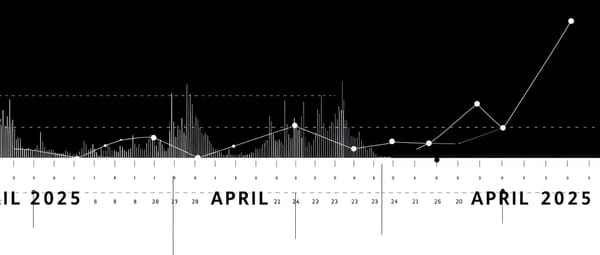

The Million-Dollar Meltdown: Crippling Costs of Radioactive Contamination

Failure to detect radioactive scrap isn't just a safety lapse; it's a financial and operational disaster waiting to happen.

Financial Ruin: When Scrap Turns Radioactive

The immediate financial impact can be staggering:

- Direct Cleanup Costs: Decontaminating a scrap yard or melting facility can easily exceed $1 million, with many incidents reaching multi-million or even tens of millions.

- Case Study: Acerinox Steel (Spain, 1998) faced estimated total costs over $26 million after melting a Cesium-137 source.

- Case Study: A Florida Steel mill's cleanup from a melted Cesium source hit $25 million. [External Link Idea: Link to an EPA or IAEA report on radioactive incidents in the metal industry for authoritative data, if a suitable non-commercial one exists.]

- Operational Shutdown & Lost Revenue: Facility shutdowns can last days or weeks, costing millions. Florida Steel's Knoxville mill lost $8 million in revenue from a 16-day shutdown, bringing its total incident cost to $14.1 million.

- Radioactive Waste Disposal Costs: Contaminated scrap, equipment, and cleanup materials require specialized, expensive disposal.

- Bankruptcy Risk: The cumulative costs (cleanup, shutdown, waste disposal, legal fees, fines) can bankrupt a company.

The Human Toll: Health Impacts Beyond Measure

- Worker Exposure: Employees face risks from external gamma rays or internal inhalation/ingestion of radioactive dust. This can lead to acute radiation sickness, burns, and long-term increased risks of cancer. The Mayapuri, India (2010) incident saw one death from Cobalt-60 in scrap.

- Public Health Risk: Melted radioactive material can contaminate products like rebar (as in the Taiwan Rebar incident, exposing ~7,000 people) or cause environmental releases (the Acerinox cloud drifted across Europe). The Goiânia, Brazil (1987) incident resulted in 4 deaths and widespread contamination from a single medical source.

- Psychological Impact: Fear, anxiety, and stress affect workers, families, and the community.

Reputational Fallout & Legal Liabilities

- Damaged Business Image: Incidents erode customer trust and attract negative publicity.

- Industry-Wide Impact: Reflects poorly on the entire recycling sector, inviting stricter scrap yard compliance measures.

- Fines & Penalties: Regulatory bodies (NRC, EPA, state agencies) can levy substantial fines for improper handling or loss of radioactive materials. For instance, Oregon companies were fined over $368,000 for illegal radioactive waste dumping.

- Lawsuits & Shipment Rejection: Liability claims and rejected/confiscated shipments add to the financial burden.

Your First Line of Defense: Essential Radiation Detection for Scrap Yards

Proactive scrap metal radiation detection is not an expense; it's an investment in survival. Several technologies are crucial:

Key Radiation Detection Equipment & Systems

- Portal Monitors (Vehicle/Gate Monitors):

- Function: Large, stationary detectors (often PVT scintillators) at entry/exit points automatically scan entire vehicles for gamma (and sometimes neutron) radiation. Considered the cornerstone for radiation monitoring in scrap yards.

- Cost: Typically $18,000 - $90,000+.

- Handheld Survey Meters / Detectors:

- Types: Geiger-Mueller (GM) counters (rugged, less sensitive), Scintillation Detectors (NaI crystals, higher sensitivity), Personal Radiation Detectors (PRDs/Pagers for worker alerts).

- Use: Pinpointing sources after a portal alarm, surveying smaller items, area monitoring.

- Cost: $800 - $10,000+.

- Spectroscopic Identifiers (Radioisotope Identification Devices - RIIDs):

- Function: Advanced handhelds (or portal features) that analyze the radiation's energy spectrum to identify specific isotopes (e.g., distinguishing NORM from Cesium-137 or Cobalt-60).

- Benefit: Extremely valuable for reducing false alarms from NORM and guiding an appropriate response.

- Cost: High end of handheld range or significantly more.

Smart Investment: The ROI of Radiation Detection Systems

The cost of a detection system (tens of thousands) is minimal compared to the multi-million-dollar cost of a contamination incident. It's affordable insurance against a business-ending event. Having robust radiation detection equipment can also be a competitive advantage.

Effective Deployment & Tackling the NORM Challenge

- Strategic Placement: Install portal monitors at primary vehicle chokepoints (weigh scales, rail spurs).

- Sensitivity Settings: Balance detection of shielded sources with minimizing false alarms from background radiation or NORM. Modern systems use algorithms for better accuracy.

- Calibration & Maintenance: Daily operational checks with a test source and annual professional calibration are vital. Detector materials (like PVT) degrade over time (e.g., 8-10 years) and may need replacement.

- Managing NORM Alarms:

- RIIDs: The best technological solution for identifying NORM.

- Procedural Differentiation: Establish tiered responses based on alarm intensity and handheld readings.

- Operator Training: Crucial for understanding NORM characteristics versus orphan sources. [Internal Link Idea: Link to an article on "Best Practices for Calibrating and Maintaining Radiation Detectors"]

Alarm! Your Scrap Yard Radiation Response Plan

A radiation alarm demands immediate, correct action. A pre-defined, practiced plan is non-negotiable.

Immediate Actions: Containing the Threat

- Alarm Verification: Re-scan the vehicle. Check for environmental factors.

- Isolation: Move the vehicle and load to a designated, secured isolation area (away from traffic, work areas, drainage).

- Risk Assessment (ALARA: As Low As Reasonably Achievable):

- Survey: Trained personnel scan vehicle exteriors with a handheld detector.

- Mark & Record: Note locations and radiation levels.

- Minimize Time, Maximize Distance, Use Shielding.

- Action Levels: If readings exceed set thresholds (e.g., 2.0 mR/hr), increase distance and await expert guidance.

Notification Procedures: Calling for Backup

- Internal Reporting: Inform the designated supervisor/RSO.

- External Reporting: Contact your State Radiation Control Program office immediately. They are your primary resource. (Pro Tip: Establish contact with them before an incident!)

- Radiation Protection Adviser (RPA): Consider getting expert advice.

Handling and Disposition: The Complex Aftermath

- Segregation (If Safe & Guided ONLY): Attempting to unload or sort material should only be done under direct guidance from authorities or an RPA. Never directly touch a suspected radioactive source.

- Storage: Secure isolated sources in a designated, shielded, labeled, access-controlled area.

- Return to Sender: Often preferred, coordinated with state agencies for DOT permits.

- Disposal Challenges: Finding disposal pathways for orphan sources is difficult and costly. Programs like DOE's Off-Site Source Recovery Project (OSRP) or CRCPD/DOE's SCATR program can assist with certain sources.

- Decontamination: If a source is breached, expect extensive, specialized, and expensive cleanup.

Fostering a Safety-First Culture: Training & Awareness for Radiation in Scrap Yards

Technology is only part of the solution. A knowledgeable team and strong safety culture are vital for adequate radiation safety in scrap yards.

Equipping Your Team: Comprehensive Radiation Safety Training

Personnel need training on:

- Radiation Fundamentals: Types of radiation, units, health risks.

- Source Recognition: Common devices, warning labels (and their potential absence!).

- Detector Operation: Proper use of your specific portal monitors and handhelds, daily checks, interpreting readings.

- Alarm Response Procedures: Your facility's specific written plan.

- Radiation Safety Practices: Time, Distance, Shielding, PPE.

- Record Keeping: Documenting alarms, surveys, actions.

(Resource Tip: EPA offers training materials like "Response to Radiation Alarms at Metal Processing Facilities." Industry associations like ISRI and private consultants also provide specialized training.)

Maintaining Vigilance: Safety as an Ongoing Process

- Refresher Training: Keep knowledge current.

- Management Commitment: Leaders must champion safety, provide resources, and follow protocols.

- Continuous Improvement: Review incidents, update procedures, stay informed on regulations and technology. Integrate radiation safety into your Environmental, Health, and Safety (EHS) program.

Secure Your Future: Prioritize Radiation Monitoring in Your Scrap Yard

The evidence is clear: radioactive scrap poses a severe threat. Complacency is not an option. Investing in radiation detection for scrap yards, robust procedures, and thorough training is a fundamental investment in:

- Business Continuity (avoiding crippling costs).

- Worker Safety.

- Environmental Responsibility.

- Reputational Integrity.

- Long-Term Sustainability and Scrap Yard Compliance.

Ignoring the risk of radiation in scrap yards is gambling with your entire enterprise. Take proactive steps now.

Call-to-Action (CTA):

Is your scrap yard fully prepared to detect and manage radioactive threats? Share your thoughts or questions in the comments below. For a personalized assessment of your radiation detection needs